From the World Economic Forum:

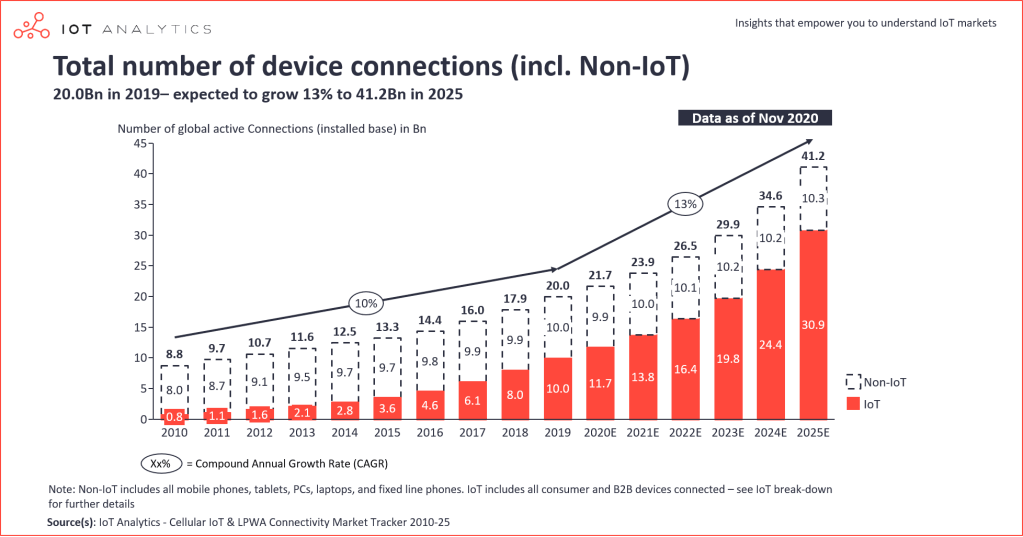

- The Internet of Things is powered by 3 emerging technologies – Artificial Intelligence, 5G and Big Data.

- When combined, Artificial Intelligence and the Internet of Things (AIoT) hold the promise of a more connected future.

- The AIoT fusion is increasingly becoming more mainstream, as it continues to transform the fundamental ways in which we live our lives and process data.

The Internet of Things (IoT) is a technology helping us to reimagine daily life, but artificial intelligence (AI) is the real driving force behind the IoT’s full potential.

From its most basic applications of tracking our fitness levels, to its wide-reaching potential across industries and urban planning, the growing partnership between AI and the IoT means that a smarter future could occur sooner than we think.

The Major AIoT Segments

So where are AI and the IoT headed together?

There are four major segments in which the AIoT is making an impact: wearables, smart home, smart city, and smart industry:

1. Wearables

Wearable devices such as smartwatches continuously monitor and track user preferences and habits. Not only has this led to impactful applications in the healthtech sector, it also works well for sports and fitness. According to leading tech research firm Gartner, the global wearable device market is estimated to see more than $87 billion in revenue by 2023.

2. Smart Home

Houses that respond to your every request are no longer restricted to science fiction. Smart homes are able to leverage appliances, lighting, electronic devices and more, learning a homeowner’s habits and developing automated “support.”

This seamless access also brings about additional perks of improved energy efficiency. As a result, the smart home market could see a compound annual growth rate (CAGR) of 25% between 2020-2025, to reach $246 billion.

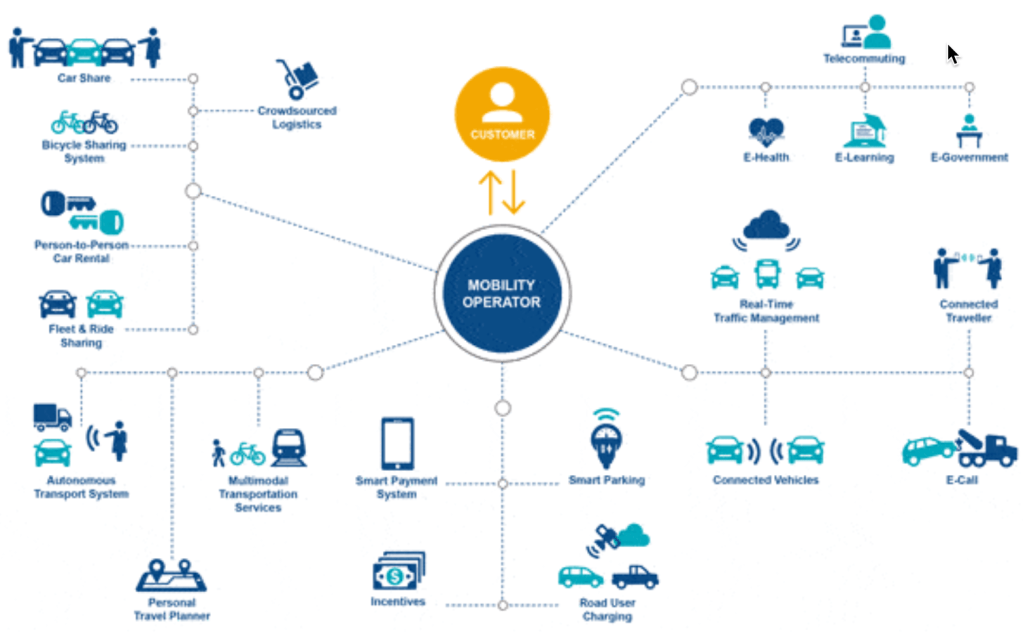

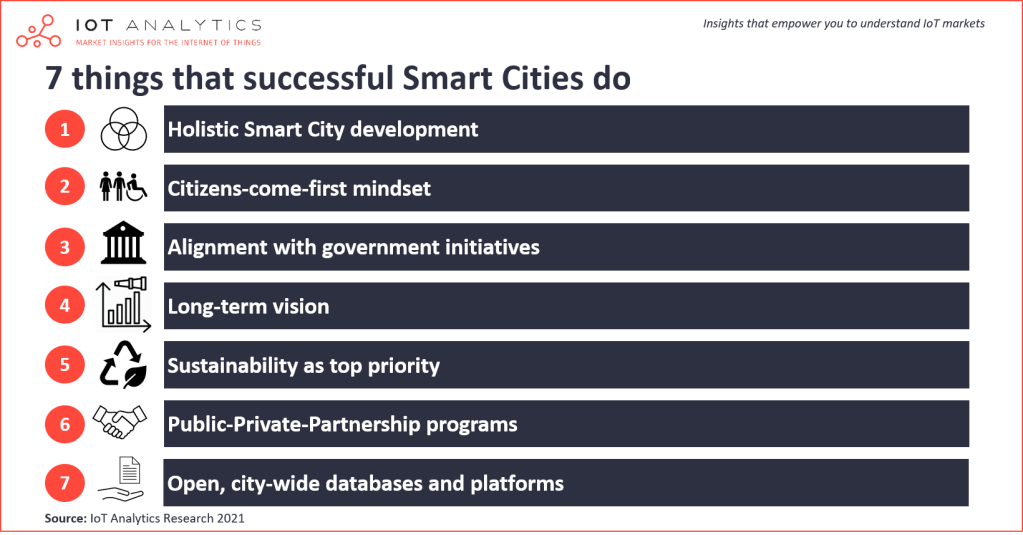

3. Smart City

As more and more people flock from rural to urban areas, cities are evolving into safer, more convenient places to live. Smart city innovations are keeping pace, with investments going towards improving public safety, transport, and energy efficiency.

The practical applications of AI in traffic control are already becoming clear. In New Delhi, home to some of the world’s most traffic-congested roads, an Intelligent Transport Management System (ITMS) is in use to make ‘real time dynamic decisions on traffic flows’.

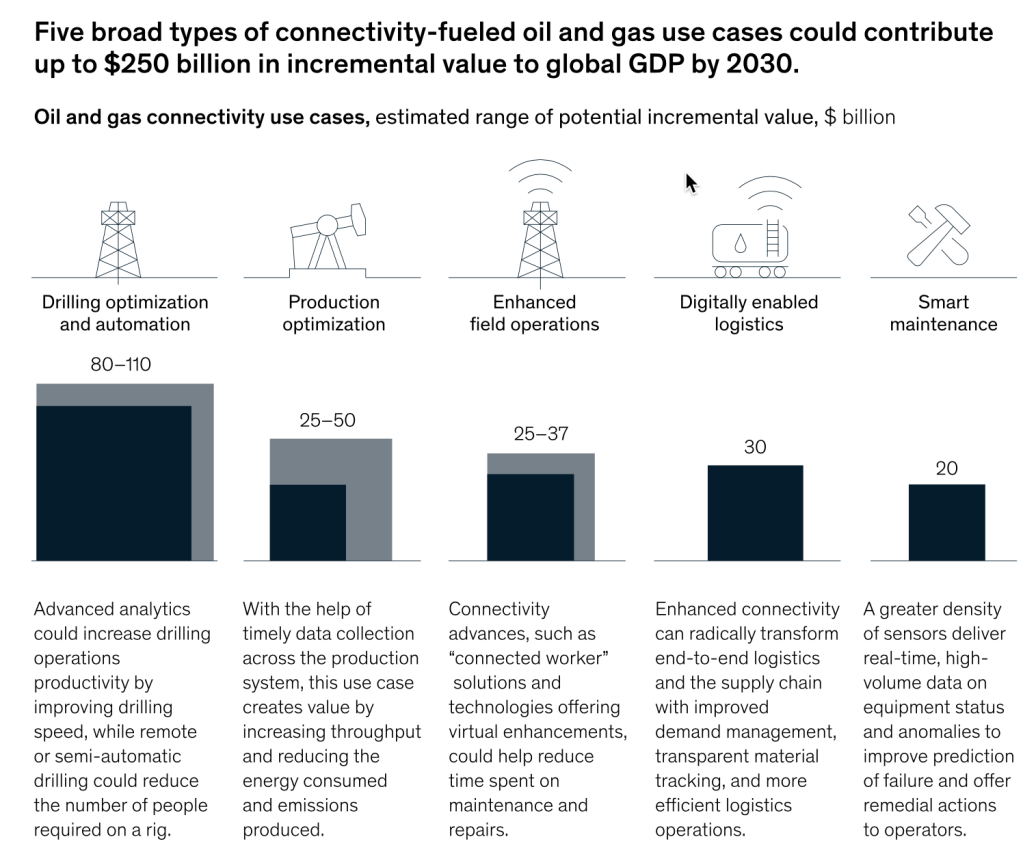

4. Smart Industry

Last but not least, industries from manufacturing to mining rely on digital transformation to become more efficient and reduce human error.

From real-time data analytics to supply-chain sensors, smart devices help prevent costly errors in industry. In fact, Gartner also estimates that over 80% of enterprise IoT projects will incorporate AI by 2022.